RPT-THE HIDDEN POWER BEHIND THE BRAND

Partnering with Brand and Engineering Leaders to Develop Go to Market Solutions

RESULTS

COLLABORATION

RPT is at the forefront of advanced graphene-based heating and cooling technologies, delivering innovative systems and the control solutions needed to power them. We partner with companies worldwide to design, develop, and seamlessly integrate our cutting-edge graphene solutions into diverse applications.

FRP Sidewalk

Sector: Municipality, Commercial, Residential

Description:

RPT collaborated with a global FRP manufacturer to create a heated sidewalk system for icy climates. By integrating advanced heating film into the FRP structure and applying a non-slip coating, the system provides safe, ice-free walkways, improving accessibility and safety in cold-weather regions.

Platform Heat

Sector: Military

Description:

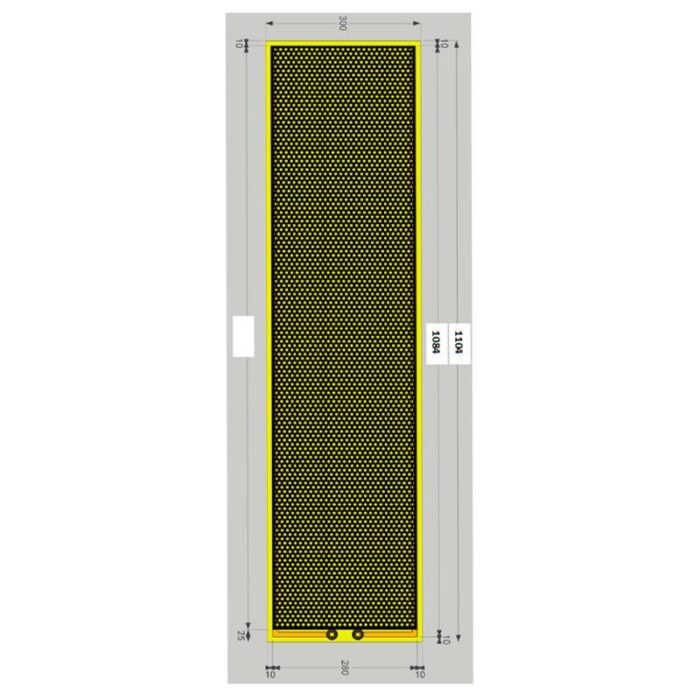

RPT developed an advanced heating solution for Arctic military operations, integrating our graphene-based heating film into 25 FRP panels. Designed for extreme conditions as low as -40°F, the system ensures uniform heat distribution and includes a rugged cold-weather control system for reliable performance.

Cheese Sauce Dispenser

Sector: Commercial/Restaurant/Convenience

Description:

RPT collaborated with an engineering firm to develop a multi-zone heating element for a leading food manufacturer. The system enhanced performance, addressed challenges of traditional hot wire systems, and cut energy consumption by 50%.

Agricultural Poultry Dehydrator

Sector: Agriculture/Livestock

Description:

RPT developed a multi-zone heating element and control system for a 1,300-pound poultry dehydrator. Featuring high-wattage FR5 heating film, the system achieves precise temperature control and improved energy efficiency, with advanced monitoring for temperature, humidity, and weight reduction.

RPT Structural Heating Applications

Sector: Building Heat

Description:

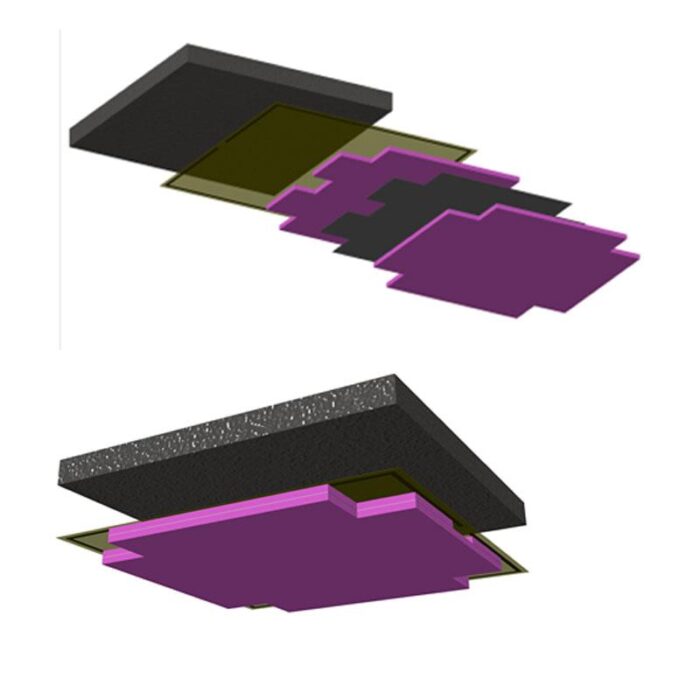

RPT designed and engineered advanced radiant heating systems tailored for structural heating applications, encompassing both above-subfloor and under-subfloor configurations. These systems were developed as energy-efficient alternatives to traditional gas-fired, baseboard, hydronic, and other conventional heating solutions.

To support a range of applications from small-scale residential installations, such as bathroom heating, to comprehensive whole-building in-floor heat management, RPT also developed modular PLC-based control systems. These systems ensure precise temperature regulation and seamless integration with building automation frameworks, optimizing performance and energy efficiency.

Cargo Trailers / Agg Trailers – Internal Trailer Solution

Sector: Structure Heat

Description:

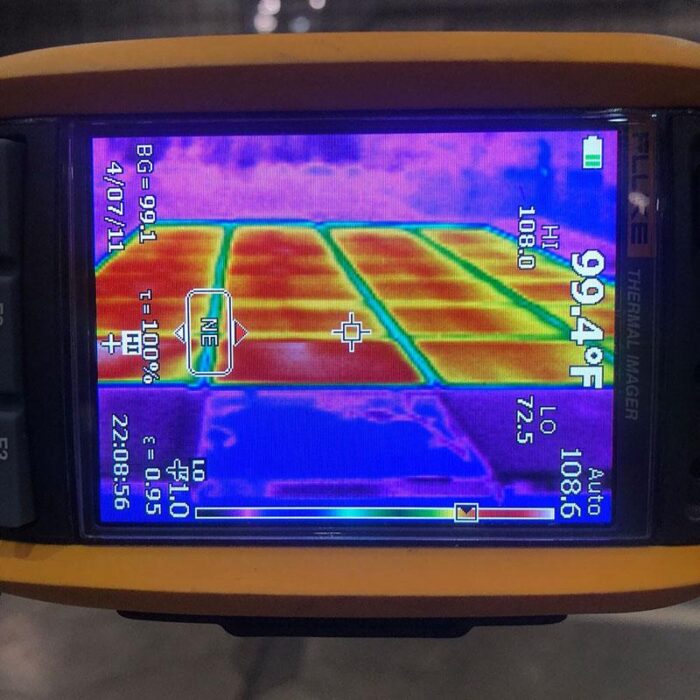

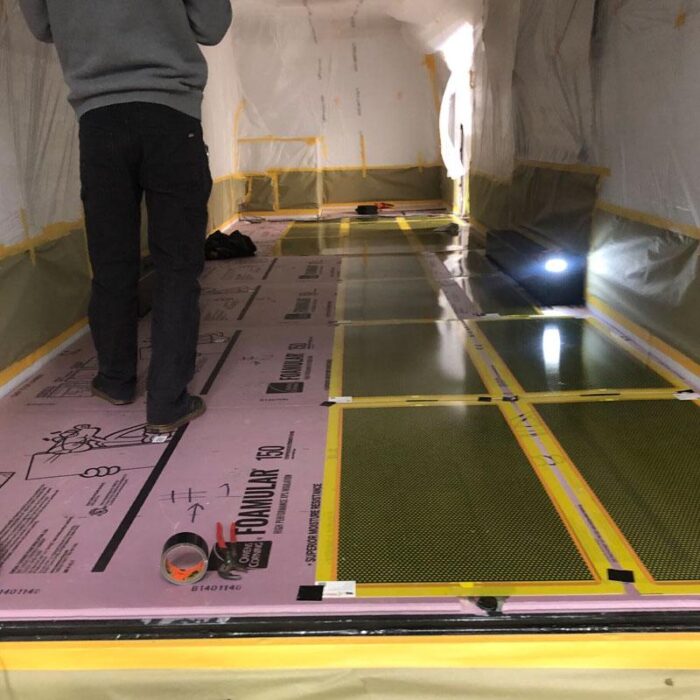

Radiant Panel Technologies developed an innovative solution to prevent large fluid tanks and pumps from freezing inside cargo trailers for a poultry depopulating trailer, ensuring reliable operation in even the harshest conditions. The system integrates RPT heat film, installed under the trailer decking, providing uniform and efficient heat distribution. This heating system is paired with advanced controls tailored to maintain optimal temperatures within the trailer, safeguarding sensitive equipment and fluids from freezing temperatures.

By embedding the radiant panels into the trailer infrastructure, the system not only protects tanks and pumps but also enhances the trailer’s overall functionality, making it a versatile option for industries requiring dependable cold-weather operations. This development highlights RPT’s commitment to pioneering practical and scalable heating solutions for specialized applications.

Cargo Trailers / Agg Trailers – Under Trailer Solution

Sector: Structure Heat

Description:

Radiant Panel Technologies engineered a retro-fit heating solution for an agricultural command center trailer to improve interior comfort while reducing liquid propane (LP) consumption by at least 50%.

The system utilizes custom-designed heat panels installed between the trailer frame cross members and directly against the underside of the trailer deck. After installation and functional testing, the trailer’s underside was insulated with 2–3 inches of closed-cell foam to enhance thermal efficiency.

To optimize control and energy use, RPT replaced the original LP furnace thermostat with a custom-programmed PLC-based thermostat. This upgraded system manages both the radiant floor heating panels and the LP furnace, ensuring seamless integration and efficient temperature regulation throughout the trailer.

Ice and Snow Melt – Pavers Patio

Sector: Ice and Snow Melt – Slip, Trip and Fall mitigation.

Description:

Radiant Panel Technologies (RPT) partnered with one of the nation’s largest developers and builders of student housing facilities to design and engineer a cutting-edge solution to replace traditional hydronic heating systems for

paver ice and snow melt applications. The objective was to create a more efficient, low-maintenance, and cost-effective alternative that would integrate seamlessly into the existing infrastructure while meeting stringent performance

and safety standards.

The solution leverages RPT’s advanced graphene-based radiant heating technology, which eliminates the need for water circulation, boilers, and associated plumbing required by hydronic systems. Instead, electrically powered heating panels were designed to fit beneath the pavers, providing consistent and responsive heat distribution to prevent ice and snow accumulation. This approach not only reduces installation complexity but also minimizes energy loss and ongoing maintenance requirements.

From an engineering standpoint, RPT conducted detailed thermal modeling and load calculations to ensure the system could handle extreme weather conditions while maintaining energy efficiency. The system was also designed to integrate with smart control technologies, allowing for precise temperature regulation and energy usage optimization. By replacing hydronic heating with this innovative solution, RPT delivered a robust and scalable system that enhances safety, reliability, and operational efficiency for large-scale student housing projects.

Farrowing Mats

Sector: Agriculture/Animal Welfare.

Description:

Radiant Panel Technologies (RPT) partnered with a leading Canadian agricultural distributor to develop a cutting-edge heated farrowing mat designed to improve piglet survival rates and enhance operational efficiency. The mat utilizes RPT’s advanced graphene-based heating film, which delivers consistent and energy-efficient heat across its surface. Encased in a durable, water-proof poly coating, the mat is engineered to withstand the demanding conditions of modern farrowing operations while ensuring easy cleaning and long-term reliability.

This innovative solution provides uniform warmth to reduce piglet stress and hypothermia, promoting healthier growth and better outcomes for producers. The low-voltage design enhances safety, while the lightweight and flexible construction allows for quick installation in various setups. By combining advanced materials and precision engineering, RPT’s heated farrowing mat offers a dependable, energy-efficient solution tailored to the needs of the Global swine industry.